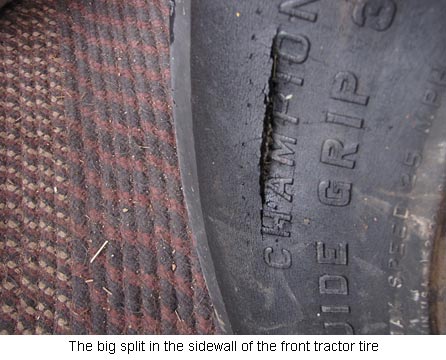

Previously, I’d taken in two front tractor tires to the Tire Shop in Cook to see if they could boot the splits in the sidewalls. No dice, the splits were too big and the guys said the boots might not work over time. So when I brought them home, Will started working on an idea for repairing them. New tires are several hundred dollars each. He figured, what the heck…

So, he began drilling holes on each side of the splits and threading wire through and through, effectively “sewing” the gaping split together. Once tight, he then coated both inside and out with a liberal coating of black Shoe Goo (silicone sealer) to reduce roughness and protect the outside from catching on field debris. Now he’s going to put two boots, one smaller and the next, (larger over the first, inside). Then it’ll be ready for a tube and back on the tractor. You can hardly see the spot where the ugly split used to be — no big lump, no roughness at all.

Of course, it remains to be seen if it’ll work, long term, but he has very little invested except for time and energy. And he thinks it will work, just like his homemade cement tractor wheel weights he made a couple of years ago. Cool, I love coloring outside the lines!

Meanwhile, I planted several more varieties of tomatoes and the first I planted are already coming up. That’s three days! The first peppers are almost big enough to transplant so that’ll be a next weekend job.

Yesterday I heard a killdeer and red-winged blackbirds singing! AND I saw a robin. This morning red-winged blackbirds were in the tree by the chicken yard. Spring’s here for sure! — Jackie

The tractor tire weights were totally awesome and so is this. I read the blog every day too, looking for problem solving ideas. I get so busy with day to day challenges that my problem solving inventiveness suffers. Thank goodness you and Will (isn’t he amazing! and when will the clones be available?) and your readers keep the ideas coming.

I did a repair like this a few years ago on a car tire (brand new) .. a 4″ split in the side wall. Took an old inner tube and cut a piece to fit the spot and made it a little bigger.. cleaned up the area with acetone or thinner and roughed it up with file, used some glue that came with a bike patch kit.. lots of glue on the tire and lots on the tube.. let it get a little tacky and put the patch in place.. took a roller like a wall paper roller 2″ type and rolled over it making sure all the air is squished out. Put is someplace warm for a couple of hours and lo and behold it held for almost the life of the tire.. good luck

Another thought. They make large , oversize patches for truck tires, most are heavy fiber reinforced and actually might bond to the Shoe Glue surface. Have tried them for this type of repair and by themselves will not take the pressure but with the wire sewing might just do the trick !!

Please do post how this works out. Have often wondered about this myself.

He is a very clever guy. I don’t post very often but I read your blog every day. Thanks.

Hope the tire trick works! Love that good old American ingenuity! Happy that you’re continuing to see all those signs of spring.

I hope the tire holds too. Do you have a loader on this tractor?

Will the Wizard. Amazing!!

Isn’t Shoe Goo wonderful? My husband uses it for all kinds of fixes! I saw some Mountain Bluebirds this past weekend, spring is here even though we have had a few snowflakes this week!

I heard Sandhill Cranes the day before yesterday. Spring is coming to the prairies….

If this repair doesn’t hold, can I suggest trying another trick? Try gluing a piece of cloth over the split from the inside, then paint it over with more Shoe Goo, and repeat with more cloth. Let it dry between layers. The combination of fibers and glue can make an incredibly strong patch.

Disclosure: I haven’t tried this trick on a tire. But I have a friend who used it to repair a water tank.

Comments are closed.