| Issue #110 • March/April, 2008 |

Last winter I got a phone call from an old friend in Arizona. One of his sons had fallen in love, gotten the girl in trouble, and run afoul of her Mexican/Indian family. A hasty marriage and real wedding ceremony was the only thing capable of defusing the situation, and the kid really wanted “Uncle Joe” to perform the wedding ceremony.

Of course the fact that Arizona’s temperatures were in the 60s and 70s, while I was shoveling a three-foot snowdrift off of my roof in sub-zero winds didn’t influence my decision to make the trip even a little bit. Yeah, right!

After the wedding I stuck around longer than I’d planned to, because everyone had already decided to erect a house for the new couple, on property his father had given them as a wedding gift. Some of the “guests” had already been at work on the project for several weeks.

|

Several older men, armed with ancient looking adzes and mattocks, shaved away at the sides of a depression carved into a bank of clay. Others shoveled these shavings into the middle of the “brick pit” they were working in. Younger men and older boys carted wheelbarrow loads of horse and burro manure, and buckets filled with creek water, to mix with the clay shavings.

|

The mixture varies according to the quality of the clay, but is usually about 10-15% manure, just enough water to achieve a plaster-like consistency, and sometimes small amounts of coarse sand.

|

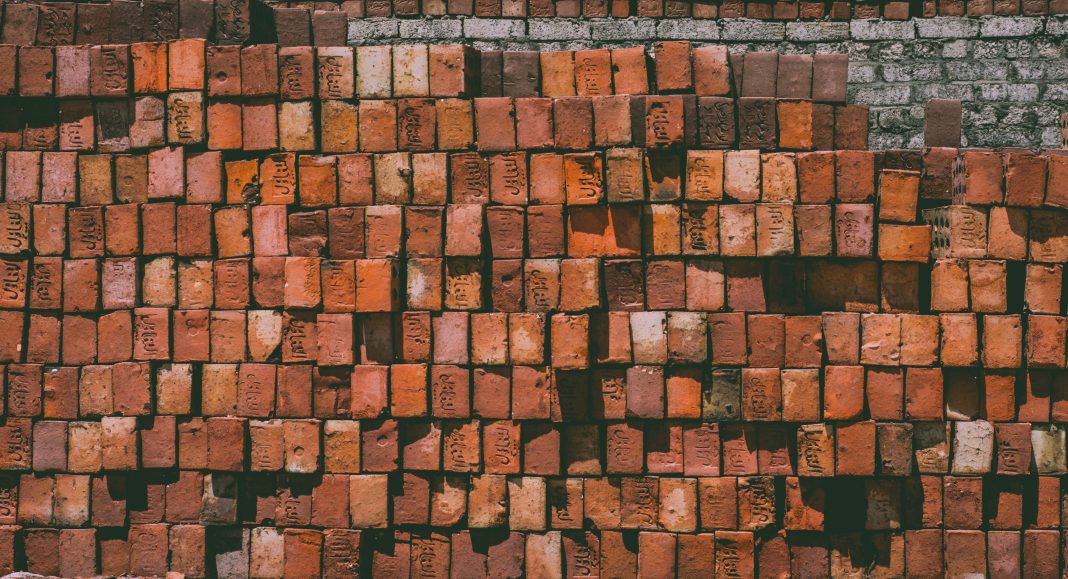

Young men and women stomped around in the sloppy mess, churning the mixture together. All the while, wheelbarrow loads of this mixture were hauled out and made into bricks using wooden molds. Then the molds were removed, regreased (by rubbing with rancid fat, or painting on a 50-50 mix of kerosene and used motor oil), and the “bricks” were left laying flat to dry in the sun. Bricks that had already dried enough to handle without falling apart were stacked on edge for further drying.

|

With everyone working together, we were producing 1,500 to 2,000 unfired bricks each day. Once enough of these bricks (about 7,500) had been very thoroughly dried by the sun and wind, they were stacked to form a large, open-topped kiln which was then filled to overflowing with wood hauled from the mountains, corn cobs carted from fields and cribs, well-dried goat, sheep, pig, and cattle manure, and just about any other sort of fuel they could collect.

|

Once lighted, this fire burned through two full days and nights, and then took another three days to cool enough to shovel away the ashes and coals. The bricks were just as hard as any you could have purchased.

After the firing, it was plain to see how the added manure does more than just hold the bricks together as they dry. During the firing, the manure in the bricks burns along with the other fuel. This not only burns the bricks harder, but leaves them porous enough to soak up some of the mortar as they’re laid, giving a stronger bond.

Essentially, the same process was used to fashion the roofing tiles. Some six and seven-inch diameter logs were sawn into two-foot lengths, split in half, and debarked. The rounded sides were greased and coated with about a ¾-inch-thickness of this same clay mixture. Once well dried in the sun, the hardened clay was very carefully removed from the wood. The tiles that didn’t break were stacked into the same type of open kiln stack, and left to complete the drying process. Those that didn’t survive removal from the “molds” were broken up and tossed back into the brick pit.

Once these tiles were totally dried out, the stack was again filled with whatever sorts of flammables could be collected together. This was then set afire, and allowed to burn itself out. Probably nearly a fourth of these tiles cracked or broke apart during the firing, but that didn’t faze anyone. They simply gave several of the smaller kids some fist-sized rocks, and set them to busting the damaged tiles into tiny bits. Later, the broken bits were used like gravel to fashion walkways around the new home.

Other logs, hauled down from the same mountains, were used to shape door and window frames, rafters and roof braces, pole-type roof sheathing, and other necessary items. There were still a few things that needed to be purchased however; nails, window glass, masonry cement, and so forth (which my friend’s in-laws happily sprang for). But for less than $1,000, the new couple had a spanking new 2,500 square-foot sturdy brick home, without owing anyone anything, except gratitude.