| Issue #87 • May/June, 2004 |

There are few things more frustrating and dangerous than working with a dull knife. In my quest for a sharp knife, I have purchased many different styles of knife sharpeners. From whetstones to oilstones, fixed-angle sharpeners to diamond dust-impregnated steels, I have used them all and have spent hundreds of dollars in the process. Which is why knife sharpening has become big business. Some sharpeners cost more than the knives.

But of all the sharpeners I have used over the years, I have had the best results with the ceramic sharpeners. Ceramic material has the hardness of glass which is much harder than steel. But unlike glass, ceramic is abrasive. And it is this combination of abrasive hardness that makes ceramic such a good knife sharpener.

However, good ceramic sharpeners start at around $25. Not bad if you’re just buying one. But I like to have one in the workshop, tackle box, toolbox, camp kitchen box, backpack, and kitchen drawer. That can get a little expensive. Of course I could just buy one or two and transfer them into the appropriate location. But that usually resulted in my ending up in the boonies with a dull knife and no sharpener. Sound familiar?

Well, here is how to eliminate that problem without wiping out your cash stash. When I recently rewired my 1930s home I ended up with a bag of those white tube insulators from the old knob and tube wiring. I found that the tube is ceramic and is an excellent knife sharpener.

You may have to scout around, but finding some shouldn’t be a problem. Ask your electrician friend to save you some tubes from the next remodel he or she does on an old house. If you don’t have an electrician friend I suggest you find one. They come in very handy. But if you can’t wait that long, then you can check your local salvage yard or recycle center. They usually have buckets of them they will sell you cheap (about two bits each). I’m not sure why they keep them. I think people like myself, who can’t bare to see anything go into the landfill, run those places.

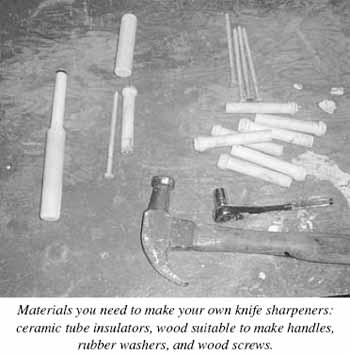

Once you have acquired your cache of sharpeners you will need some 4½-inch wood screws to attach them to wooden handles. Be sure the head of the screw is bigger than the hole in the tube but smaller in diameter than the outside diameter of the tube.

Being the pack rat that I am, I never throw out broken handles from rakes, brooms, and such. They just come in way too handy for window stops, file handles, and in this case, knife sharpener handles. If you don’t have an old handle, a ¾-inch dowel from the local hardware store will work.

To use it, draw the knife across the tube away from the handle. Keep the knife at about a 20 to 30-degree angle. Two or three minutes on each side and your knife should be sharp enough to shave with. As with other ceramic sharpeners, it will become darkened with the steel it removes. But it cleans up easily with cleanser and water.

That’s all there is to it. You now can have a great ceramic knife sharpener wherever you need one. With the money you save you can buy that hunting knife you have been wanting. And it keeps one more thing out of the landfill.

|