| Issue #133 • January/February, 2012 |

|

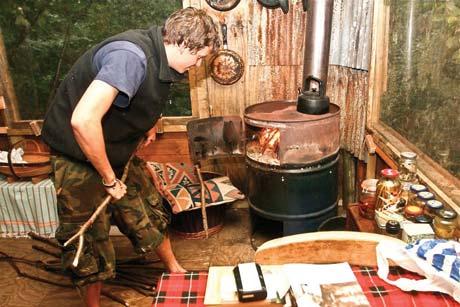

With a bit of nip and tuck using a few basic tools, an old oil drum can be transformed into a fantastic woodburning stove. Although the thin sheet metal used to make oil drums may not hold the heat as well as a stove built from an old gas canister, it does have a couple of positives: it is incredibly light and transportable and no specialized tools are required for construction. Its light weight makes it an ideal stove for temporary situations, such as a winter hunting camp. Because the firebox is elevated off the ground, it would also work in an ice fishing hut.

For more than six months, this very stove kept me nice and warm while I was living in my tree house. It also provided an excellent surface for cooking on at an ideal height and kept the kettle singing all day long!

|

There are many places to get your hands on an old oil drum: a visit to the local garage or mechanic is the best place to start (they will probably give it to you free), and demolition yards are also quite productive. The stove itself will cost less than $25 to build, but you will have to spend a bit of money on the stovepipe, flash plate, and rain hat.

Tools you will need: jigsaw and two metal cutting blades (in case one breaks), power drill with drill bits (all purpose bits or those suitable for metal), flat head screw driver, pliers, metal file (for getting rid of any sharp edges), and thick black marker pen.

Materials:

1 55-gallon steel drum

8 L-brackets (3×3-inch)

1 hinge (3-inch)

22 Phillips head bolts (M5x20) with square nuts and washers

10 self-tapping screws (to fit stove pipe onto stove)

6 coach/carriage bolts (for fitting the draft) with nuts and washers (M5x20)

Black wood stove spray paint

Directions

Drill a hole at the edge of the top of the drum (the end with the screw-on caps). Using a jigsaw with a metal cutting blade, cut around the edge of the drum and remove the “lid.” (This will eventually be bolted on the inside as the firebox floor; the open end of the barrel will be the bottom of the stove.) Remember, before making any cuts with the jigsaw, you will have to drill a hole to insert the jigsaw blade. Mark out any openings you will need to cut out using a thick black marker pen.

Move the barrel to an open area and make a small fire in the bottom to burn off any excess oil or residue still clinging to the insides (remember to stand well back). Once cooled, you can begin work.

To make the stove door, cut two rectangular openings in the front of the barrel on the side opposite the seam. There should be two raised rings running around the barrel, dividing it into three sections. The smaller rectangle (12×8 inches) should be cut in the top section (closest to the closed end of the barrel) and will be the opening of the firebox. Keep the smaller cutout to use for the draft plate. The larger rectangle (14×10 inches) should be cut out of the bottom section (near the open end of the barrel); this larger rectangle will be used for the firebox door.

The hole for the stovepipe should be positioned on the top surface near the back edge. You will need a stovepipe with a diameter of 5 inches, although the smaller the better. Position the edge of the stovepipe about 1 inch from the back of the stove top and draw around it with a felt-tip pen. Next, draw a 4-inch circle inside the 5-inch circle. By cutting out the smaller circle, the remaining ½-inch border can be cut into tabs that can be bent up when fitting the stovepipe. You can then fit the stovepipe with L-brackets or self-tapping screws.

The firebox floor is made from the round disc that was cut out of the top of the barrel. This will be supported by L-brackets. Six brackets spaced evenly, with an extra one at the door, work well, but it doesn’t hurt to use more if you wish. Drill holes in the barrel about one inch below the upper ring. Make sure they are all the same distance from the top, about two inches below the door opening. Bolt the brackets to the disc first, then lower the floor into the barrel and bolt it into place. This is a lot harder than it sounds, and is easier with two people. There will be a crack around the edge on the inside that can be sealed with exhaust pipe filler from underneath.

The air draft at the bottom of the door is quite tricky to make. Cut a 2½x9-inch piece from the smaller leftover rectangle. Make vertical markings every ½-inch from end to end. This draft slide is held in place by six carriage bolts. These have a round shaft with threads, topped by a square, which is then topped by a rounded head. If in doubt, your DIY shop can help you locate them.

Drill five holes (two at the top, two at the bottom, and one on the left end see photos below for placement) big enough for the shaft of the bolt to pass through, but not big enough for the square to pass through. The slide will move back and forth in the space between the stove door and the round head of the carriage bolts. Install the five bolts and move the slide to the left as far as possible. Then drill a hole in the center through the slide and the door. The size of the hole will be dictated by the knob you use. Through this hole bolt the slide to the door. This will hold everything in place while you drill the air holes. Next, drill three rows of 3/8-inch air holes on each side of the slide, ½-inch apart. Be sure to drill through both the slide and the door at the same time so the holes will all line up when the draft is open. The plain ½-inch spaces will cover the holes in the door when the draft is closed. Remove the slide and drill or cut an opening in the door to allow for the movement of the knob screw. Replace the slide and install the sixth carriage bolt on the right end. Allow space so that the slide covers all the holes in the door when the draft is closed. Finally, attach the knob. This involves a lot of drilling, but it makes a great air draft.

Attach the door with a 3-inch hinge on the left hand side.

The door latch is made using two 3×3-inch L-brackets. Cut one L-bracket down to 3×1-inch and carve a ¼-inch notch into it that will accept the other “latch” L-bracket. It’s a bit fiddly to get a snug fit, but make adjustments until the door stays tightly shut.

Be sure to test the stove outside a few times to ensure there are no weak points or cracks. Do ensure the draft works and draws the smoke out of the stovepipe without any escaping; remember the stove will be used indoors! The stove does give out a fair bit of heat, so make sure the floor and walls around it are fireproofed or are at least a good 12 inches away. To make the stove look presentable, you can give it a good scrub down with a wire brush and then spray it with black wood stove spray paint about three cans should cover it.

Please sent use boiler water tank that used with firewood