Page Not Found

Sorry! The page you were looking for is no longer available or the link has expired. If you were looking for a specific product, you can search our store.

While you’re here, take a look through some of our great articles!

A contrary guide to feeding animals

By Beth Greenwood

Issue #135 • May/June, 2012

The Purinas, Cargills, and Con-Agras of the world would have you believe that they and they alone have...

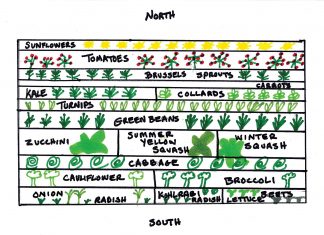

Use Non-Hybrid Seeds and Save Big Bucks in This Year’s Garden

By Jackie Clay

Issue #51 • May/June, 1998

Every person who is striving for self-reliance should, and most do, plant a garden from which to raise...

Build Your Own Hoop House

By Jackie Clay-Atkinson

Issue #171 • May/June, 2018

I’ve had my own garden for more than half a century, and I have learned a few things...

Naughty Peppers

By Alice B. Yeager

Photos by James O. Yeager

Issue #62 • March/April, 2000

If you are prudish, narrow-minded or puritanical, read no further as this article...

Friends and Fellow Citizens: The period for a new election of a citizen, to administer the executive government of the United States, being not far distant, and the time actually arrived, when your thoughts must be employed in designating the person who is to be clothed with that important...

By Tom Kovach

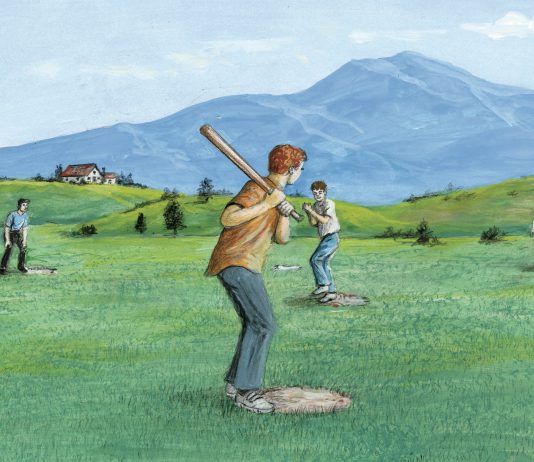

Growing up on a farm in north-central Minnesota wasn’t all chores and hard work … although there was plenty of that too. But back in the l950s and early l960s when I was growing up there were a number of small farms like ours within a mile...

By Tom Kovach

Issue #65 • September/October, 2000

Having the best vegetable garden in the village might put food on the table and make some money at the market, but it also can cause some problems. Or so it was with my grandfather, the mayor of a small village in Hungary,...