Page Not Found

Sorry! The page you were looking for is no longer available or the link has expired. If you were looking for a specific product, you can search our store.

While you’re here, take a look through some of our great articles!

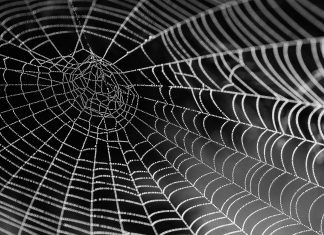

Get to know your spiders

By Jerry Hourigan

Issue #109 • January/February, 2008

Every landowner and homeowner creates the perfect environment for spiders. Not intentionally, of course, but spiders seem to...

Put Your Garden to Bed for the Winter

By Jackie Clay

Issue #95 • September/October, 2005

During the crispy fall afternoons, we listen often and intently to the weather forecasts. "It's going to be...

A Child’s Garden — More than Child’s Play

By Jackie Clay

Issue #69 • May/June, 2001

There are many things parents can give their children, other than plastic toys or a few bucks to...

Gardening with a Chicken Tractor

By Brianna Stone

<!--

>!>!>!> Make content-2-col-left = 70% if activating this column

-->

Issue #161 • September/October, 2016

This spring, my parents let me enlarge my...

By O. E. MacDougal

Issue #154 • July/August, 2015

There was a time when it was thought that a defining difference between humans and animals was: we use tools, they don't. But, in the last few decades, it's been discovered that many animals are tool users.

Before we go further, let's define...

By Alice B. Yeager and James O. Yeager

Issue #115 • January/February, 2009

I was a girl of 8 when the stock market crashed in 1929. It was the Great Depression, and unless you were living during the Depression years, you can't really understand how tough they were. Our parents knew,...

By Marlene Parkin

Issue #22 • July/August, 1993

Many of the quilts of yesterday took a lifetime to make. Perhaps the mystical part of quiltsthe aspect that makes them almost humanis the countless hours of work and devotion it took to create a masterpiece of the heart.

Beyond their beauty and usefulness,...