Page Not Found

Sorry! The page you were looking for is no longer available or the link has expired. If you were looking for a specific product, you can search our store.

While you’re here, take a look through some of our great articles!

Good-bye old friend

By Lucy Shober

Issue #27 • May/June, 1994

Big Poney died today. He was 34 years old and had been going down pretty rapidly over this...

The Potato Hole

By Sylvia Gist

Issue #137 • September/October, 2012

Carrots go in sand in the green pail and potatoes can be sorted by type into plastic mesh...

Grow Garlic and Reap Health Benefits

By Alice B. Yeager

Photos by James O. Yeager

Issue #98 • March/April, 2006

Garlic is one of our oldest herbs on record. Anyone can grow garlic...

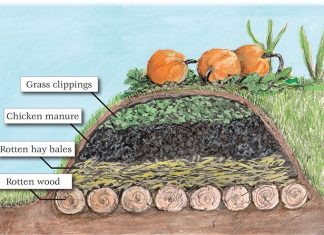

Grow some winter squash this year

By Lisa Nourse

I love summertime — I love the green of the trees, the warm weather, and growing my own food. I especially love...

By Don Lewis

Issue #176 • April/May/June, 2019

The year was 1834, a year that didn’t really stand out as all that particularly important in American history. But like any other year, it had its share of firsts. The first railroad tunnel was completed in Pennsylvania and the United States Senate...

By John Silveira

Issue #30 • November/December, 1994

(This is a four-part series. Click the links to navigate to parts one, two, three, and four.)

(When we left off last issue, O. E. MacDougal and John Silveira were travelling from Ojai, California, to Ashland, Oregon. Mac was talking about the First Ladies...

By O. E. MacDougal

Issue #154 • July/August, 2015

There was a time when it was thought that a defining difference between humans and animals was: we use tools, they don't. But, in the last few decades, it's been discovered that many animals are tool users.

Before we go further, let's define...